The oil and gas industry is a complex and multi-level system involving various human activities. While it may seem that the complexities are only related to the extraction of natural resources, the transportation of gas and oil products is an equally important and integral process within the oil and gas industry. This is because, in order to benefit from the advantages of hydrocarbon fuels, these products must first be transported to places of processing and final use.

Currently, the transportation of oil and gas is carried out through various means, including railway and water transport. However, pipelines remain the most cost-effective, safe, and environmentally friendly solution.

Two main types of pipelines are distinguished based on their length and tasks:

1. Main pipelines are used for transporting oil and oil products over tens of thousands of kilometers, both within Russia and beyond its borders. Delivery takes place from extraction or production sites to end points, industrial facilities for further oil processing, or transportation hubs.

2. Field pipelines are used to transport oil from extraction sites to the main storage location.

Main Pipeline Transportation

Main pipeline transportation plays a significant role in the fuel and energy complex (FEC) and is of great importance for the economic well-being of a country. In Russia, a comprehensive network of main oil pipelines with a total length of over 72,000 kilometers has been established, passing through most of the country's regions. Approximately 90% of the oil produced in the country is transported through these pipelines.

For the effective operation of any system, including pipelines, continuous monitoring of their condition and integrity is necessary. The vast length, passage through different climate zones, and remote locations significantly complicate pipeline maintenance and monitoring. Therefore, in order to prevent economic losses, accidents, and malfunctions, remote methods of pipeline condition monitoring must be applied.

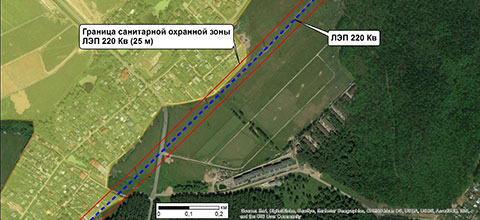

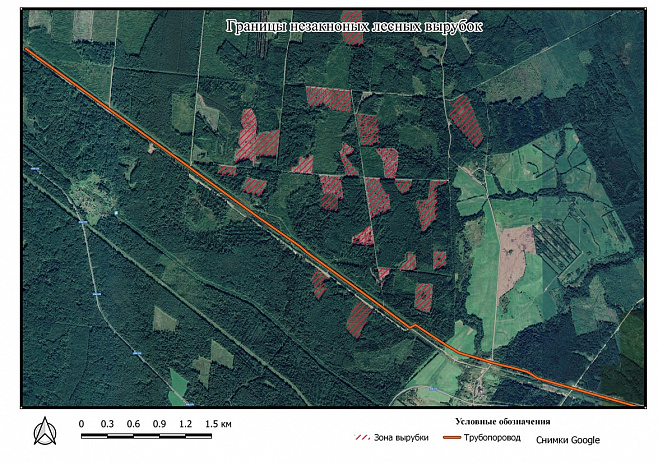

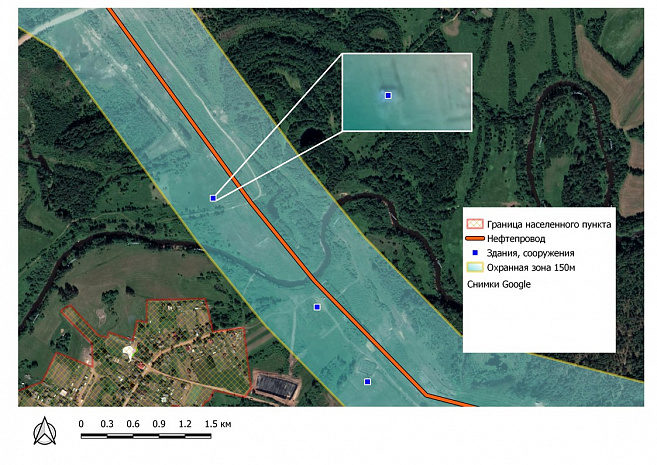

Pipeline malfunctions can have both internal and external causes. Special equipment and chemical agents are used to prevent and address internal issues, including specific pressure sensors, anti-corrosion additives, and infrasound monitoring systems. External factors that affect pipeline integrity must be monitored remotely. To ensure the safety of pipelines, evacuation zones (50 meters) and security zones (up to 500 meters) have been designated. In pipeline evacuation zones, any activities, such as unauthorized deforestation, mineral extraction, and even construction, are prohibited. In forested areas along the pipeline route, authorized tree felling is carried out to prevent trees from falling and damaging the pipeline. The preservation and integrity of evacuation zones are just as important as the preservation of the pipelines themselves because "prevention is easier than correction."

Remote Pipeline Condition Monitoring

Remote pipeline condition monitoring is currently carried out by piloted aviation (helicopters and airplanes) and high-mobility vehicles. These traditional methods are not only labor-intensive but also very expensive. More cost-effective methods of remote monitoring have replaced them—unmanned systems and satellite imaging. Unmanned aerial vehicles (UAVs) have certain advantages in terms of ultra-high spatial resolution. However, their use still requires on-site visits by specialists, which entails additional expenses. Moreover, UAVs are not suitable for prolonged use in extremely cold conditions, so operators sometimes have to work in harsh environments. With satellite monitoring of pipelines, access to a computer is sufficient.

The most modern monitoring method is a combined one, where satellite images in a wide range of electromagnetic waves are used at the initial stage. As anomalies on the pipeline route are decoded and identified, decisions are made regarding local UAV imaging. This approach allows simultaneous planning of activities to address pipeline violations or damage, as well as environmental concerns.

Satellite imaging is the most cost-effective method, with data quality being only slightly inferior to images from most UAVs (30 cm compared to 20 cm). Figure 1 shows the cost of one hour of pipeline monitoring using various means.

There are several advantages of satellite imaging over UAV (Unmanned Aerial Vehicle) imaging:

- Legislative framework: To commence UAV imaging, a series of permits from government authorities are required, which can take several months depending on the territory. This is due to the use of a country's airspace and flight regulations. Furthermore, each drone must be registered. All of this significantly impacts project timelines. After completing the imaging, it needs to be declassified by special government agencies because any imagery obtained from the air automatically falls under the "classified" category. In contrast, satellite imaging does not require approvals from government authorities and additional permits, and the obtained data is not classified. This significantly reduces project timelines and costs.

- Speed of obtaining materials: The most modern and powerful UAV can capture approximately 100 square kilometers in one flight. In contrast, a single pass of a satellite can cover an area of up to 600 square kilometers.

- Speed of image processing: The size of a satellite image significantly exceeds that of a UAV image (by 5–40 times). This makes it easier and faster to process initial data, including image stitching, color correction, and orthorectification. Moreover, most spatial data processing software is exclusively adapted for satellite imagery, incurring additional expenses when using UAV data.

Why Regular Pipeline Condition Monitoring is Necessary

One of the main reasons why regular pipeline and evacuation zone monitoring is essential is to preserve the environmental well-being of the pipeline's surrounding areas. The state is gradually increasing penalties and introducing various additional sanctions for environmental damage (Figures 2 and 3). In particular, in 2007, the principle of multiple damages was introduced, where fines for forest law violations and soil damage are calculated based on four times the value of the tree species affected.

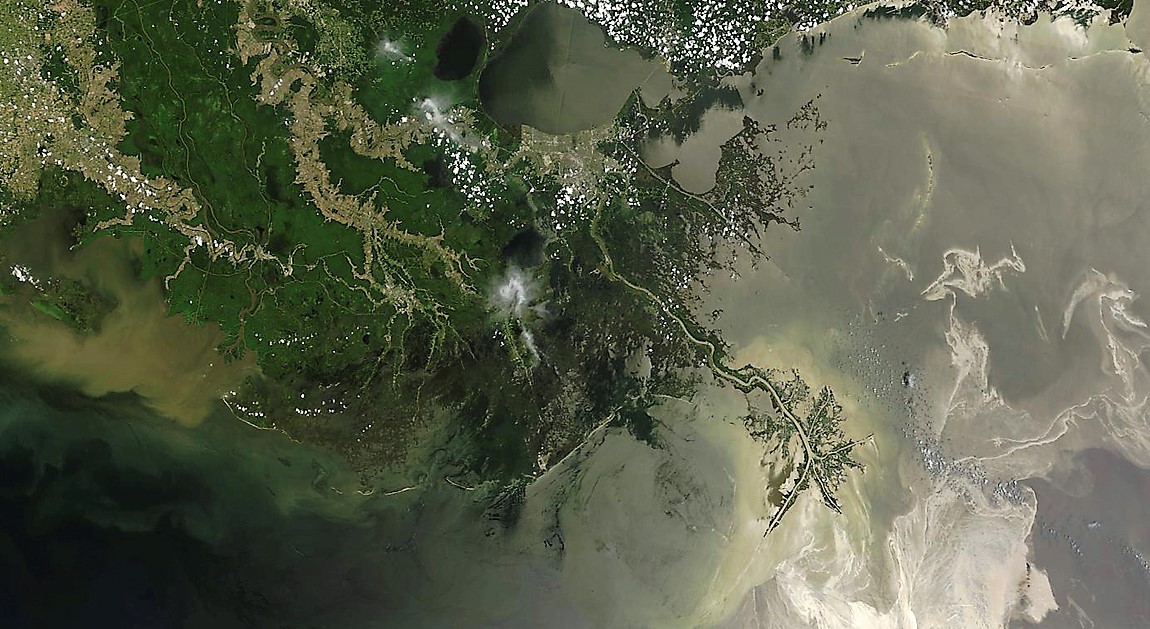

Last government decrees require oil and gas companies to submit internal pipeline reconstruction programs to the government commission for fuel and energy complex issues. In 2016, several oversight bodies compiled a comprehensive list of polluted lands using satellite imagery data. Concurrently, the Ministry of Natural Resources of Russia advocates for a hundredfold increase in fines for concealing oil spills, unpreparedness for their elimination, or providing incomplete information about polluted areas. Near-Infrared (NIR) and Short-Wave Infrared (SWIR) ranges of satellite imaging are used to detect polluted areas and damaged vegetation.

Satellite imaging, combined with the latest achievements in information technology, allows for a significant acceleration of pipeline and protective zone monitoring through deep learning-based satellite image classification. By deploying satellite image processing algorithms, GIS specialists can survey and document foreign objects, encroachments in buffer zones, and oil contamination many times faster than traditional visual interpretation. The only challenge in automated interpretation is the accumulation of territory standards. However, companies with experience in satellite image processing have substantial standard databases, enabling them to start surveying immediately. Additionally, the use of multi-temporal images allows for monitoring changes on the ground, automatically detecting all changes in the area, from deforestation to construction.

Leading global companies in the space industry, such as Maxar Technologies Inc (formerly DigitalGlobe), have developed geoprocessing platforms for automated satellite image processing, interpretation, and object identification. For example, Maxar's GBDX (Geospatial Big Data) product allows the utilization of a multi-year archive of satellite images with the highest spatial resolution and algorithms developed by leading IT companies in image interpretation. The program runs on Amazon's servers, speeding up the processing of vast amounts of remote sensing data hundreds of times over.

The detection of pollutants along pipeline routes is also of great importance.

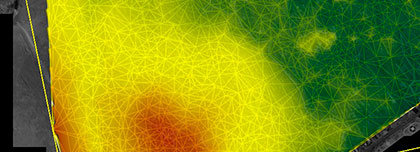

There is a remote sensing service that utilizes satellites like Dove for daily scanning of the Earth's surface and collecting images specifically of pipelines. Automatically, after the image is loaded, vegetation indices are calculated, vegetation health values are generated, and change detection analysis is performed. Deterioration in vegetation health serves as a signal for an abnormal situation along the pipeline route and may be related to the release of pollutants. This software acts as an early warning system, regularly assessing the right to monitor and quickly helping mitigate surface and underground emissions, accurately identifying problem areas (Figure 4).

Fig. 3. Identified problem areas based on vegetation assessment on the pipeline route

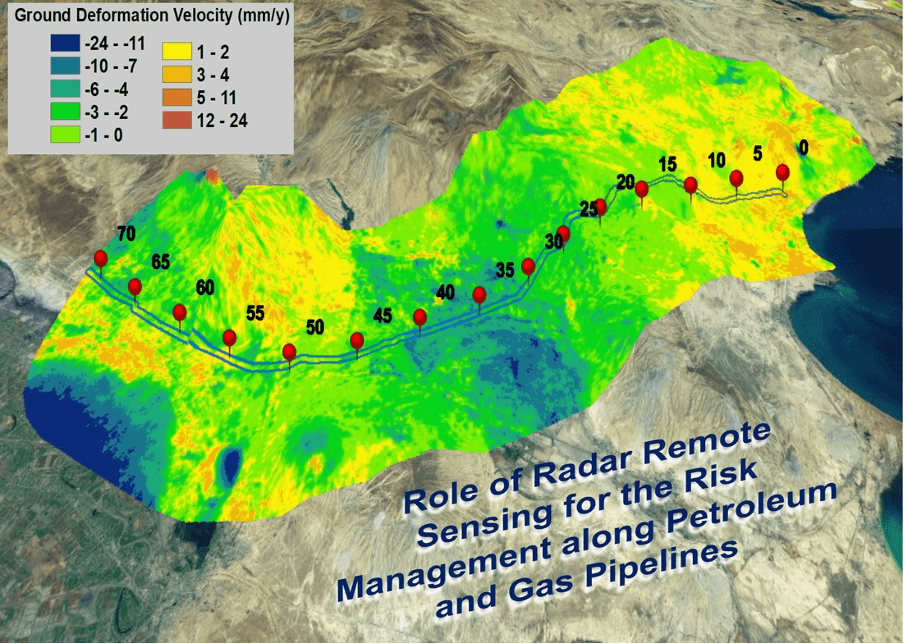

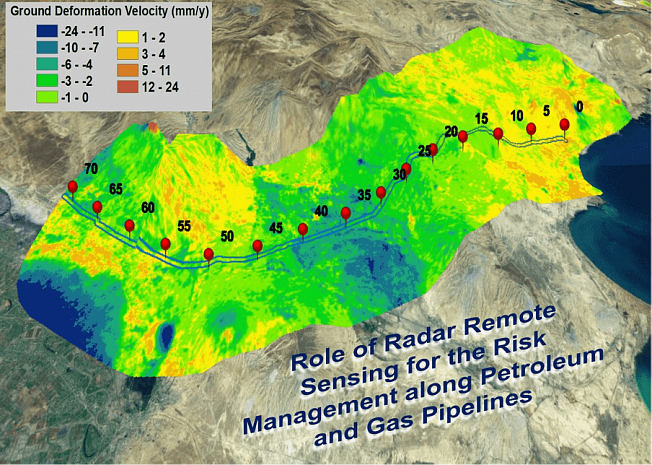

Ground deformation detection along the pipeline route

Using data from satellite imagery, radar imagery, and UAVs, automated quantitative assessment of surface deformations and their natural and anthropogenic drivers is conducted along, for example, seismically active underground oil and gas pipelines, using Permanent Scatterer Interferometry (PS-InSAR) and Small Baseline Subset (SBAS) analysis. This approach significantly improves ground deformation monitoring, provides an assessment of geological hazards and preventive measures along pipelines. The diverse spatial distribution and variability of ground movement processes along pipelines have shown that a common geological and geotechnical understanding of the study area without remote sensing monitoring is insufficient to identify and address all critical subsidence and uplift areas for pipeline operators.

Fig. 4. Displayed ground deformation levels on the pipeline route

For real-time monitoring of a main pipeline and buffer zones, as well as assessing the impact on the environment, please contact "Innoter" at +7 495 245-04-24 or send an email to innoter@innoter.com. Years of experience in using satellite imagery in the oil and gas industry will help you solve your tasks quickly and efficiently.

Monitoring the technical condition of pipelines using satellite imagery and UAVs is one of the methods that can be used to ensure the safe transportation of oil, gas, and other liquids through pipelines in various operating conditions.

Systems for diagnosing and monitoring the technical condition of pipelines include various equipment that can be used to detect defects and issues in pipelines. These can be systems for monitoring temperature, pressure, and other parameters, as well as non-destructive testing systems such as ultrasonic devices and X-ray machines.

However, the use of satellite imagery and UAV methods can be a valuable complement to existing methods for monitoring the technical condition of pipelines. They can be particularly useful for detecting damage to objects located in hard-to-reach places and for monitoring a large number of objects over large territories.

It is also important to note that systems for monitoring the technical condition of pipelines must operate in various operating conditions, including extreme conditions such as high temperatures and low temperatures, high pressure, etc. This may require the use of special equipment and methods to ensure the accuracy and reliability of the data obtained during pipeline monitoring.