Sat-Sun: Non-working days

The oil and gas sector is a complex and multi-level system of interactions between various human activities. It may seem that the difficulties are only related to the extraction of natural resources, but the transportation of gas and oil products is no less important and an integral process of the oil and gas sector, as to utilize the benefits of hydrocarbon fuel, the products must first be delivered to processing and end-use locations.

Currently, oil and gas transportation is carried out in various ways, including by rail and water transport. However, pipelines remain the most cost-effective, safe, and environmentally friendly solution.

There are two main types of pipelines, depending on their length and the tasks they solve:

1. Trunk pipelines transport oil and petroleum products over tens of thousands of kilometers both within Russia and beyond. Delivery occurs from production or extraction sites to end points, industrial enterprises for additional oil processing, or transport hubs.

2. Field pipelines serve to transport oil from the extraction site to the main storage location.

Trunk Pipeline Transport

Trunk pipeline transport plays an important role in the fuel and energy complex (FEC) and is significant for the economic state of the country. In our country, an extensive network of trunk oil pipelines with a total length of over 72,000 km has been created, passing through the territories of most subjects of the Russian Federation. About 90% of the oil produced in the country is transported through them.

For the effective operation of any system, including pipelines, constant monitoring of functionality and integrity is necessary. The vast length, routing through different climatic zones, and remote locations significantly complicate the maintenance and monitoring of pipeline conditions. Therefore, to avoid economic losses, accidents, and malfunctions, methods of remote monitoring of pipeline conditions must be applied.

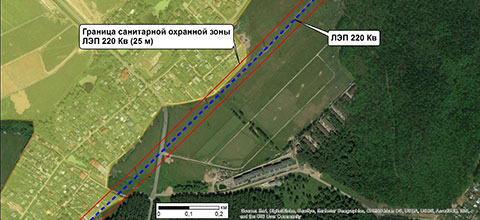

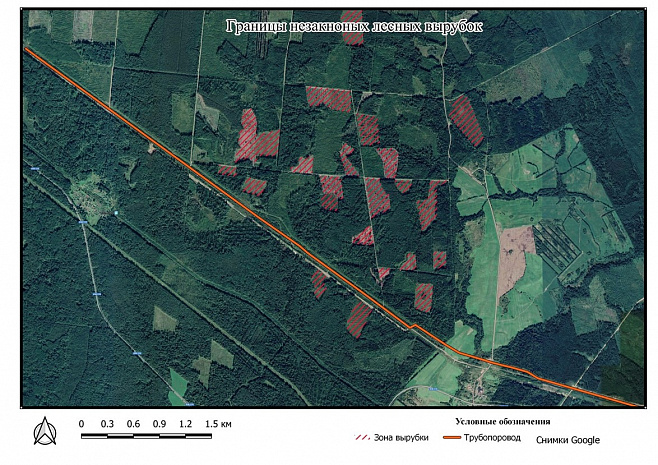

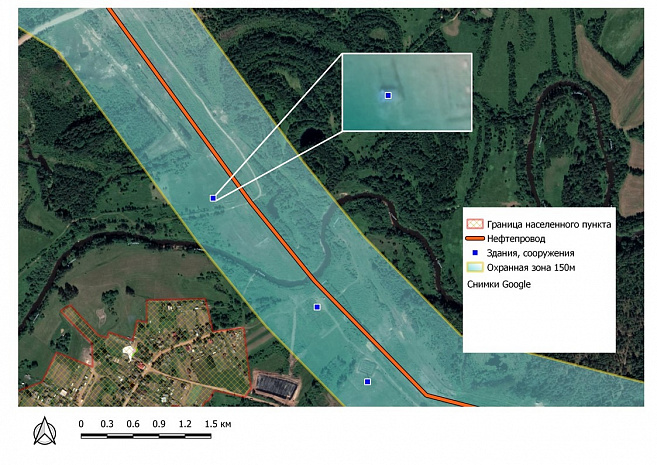

The causes of pipeline malfunctions can be both internal and external. To prevent and eliminate internal problems, special equipment and chemical agents are used: specific pressure sensors, anti-corrosion additives, and infrasound monitoring systems. External factors affecting the integrity of pipelines need to be monitored remotely. For the preservation of pipelines, withdrawal zones (50 m) and protective zones (up to 500 m) have been designated. In the withdrawal zones of the pipeline, any activity is prohibited, such as unauthorized logging, mineral extraction, and even construction. Along the pipeline route in forested areas, sanctioned logging is carried out so that trees cannot fall and damage it. The preservation and inviolability of withdrawal zones are as important as the preservation of the pipeline itself because "prevention is easier than correction."

Remote Monitoring of Pipeline Condition

Remote monitoring of pipeline condition is currently carried out by manned aviation (helicopter and airplane) and high-passability vehicles. These traditional methods are not only labor-intensive but also very expensive. They have been replaced by more cost-effective remote monitoring methods — unmanned systems and satellite imaging. Unmanned aerial vehicles (UAVs) have certain advantages in terms of ultra-high spatial resolution, but their use still requires the physical presence of specialists on-site, leading to additional costs. Moreover, UAVs are not yet suitable for prolonged use in severe cold conditions, so the operator sometimes has to be personally present in harsh environments. With satellite pipeline monitoring, it is sufficient to have only computer access.

The most modern monitoring method is combined, where satellite images in a wide range of electromagnetic waves are used in the first stage. Based on the interpretation and detection of anomalies in the pipeline route, decisions are made on local UAV imaging, allowing for simultaneous planning of work to eliminate violations or damage to the pipeline or the surrounding environment.

Satellite imaging is the cheapest, and the quality of data is only slightly inferior to images from most unmanned systems (30 cm versus 20 cm). Figure 1 shows the cost of one hour of pipeline monitoring using various means.

Satellite imaging has several other advantages over UAVs:

- Legal framework. To start UAV imaging, several permits from government authorities are required, which can take several months depending on the territory. This is related to the use of the country's airspace and flight regulations. Additionally, each UAV must be registered. All this significantly affects the time frame for completing the work. After the imaging is completed, it must be declassified by special government bodies since any image obtained from the air is automatically classified. Satellite imaging, unlike UAV imaging, does not require approvals from government authorities and additional permits, and the obtained data are not classified. This significantly reduces the time required to complete the work and lowers its cost.

- Speed of obtaining materials. The most modern and powerful UAV can capture about 100 km of territory in one flight. Meanwhile, a satellite image taken in one pass covers an area of up to 600 km.

- Speed of image processing. The size of a satellite image significantly exceeds the size of a UAV image (by 5–40 times). This facilitates and speeds up the initial data processing in terms of image stitching, color, and orthorectification. Also, most spatial data processing programs are exclusively adapted for satellite imaging, causing additional costs when using UAV data.

Why Regular Pipeline Condition Monitoring is Necessary

One of the main reasons why it is necessary to regularly conduct monitoring of pipeline conditions and withdrawal zones is to maintain the ecological well-being of the area through which the pipeline passes. The state is gradually tightening penalties for environmental damage, increasing fines, and introducing various additional sanctions (Figures 2, 3). In particular, in 2007, the principle of so-called multiple damages was introduced, where fines for violating forest legislation and soil damage are calculated based on four times the cost of the forest-forming species.

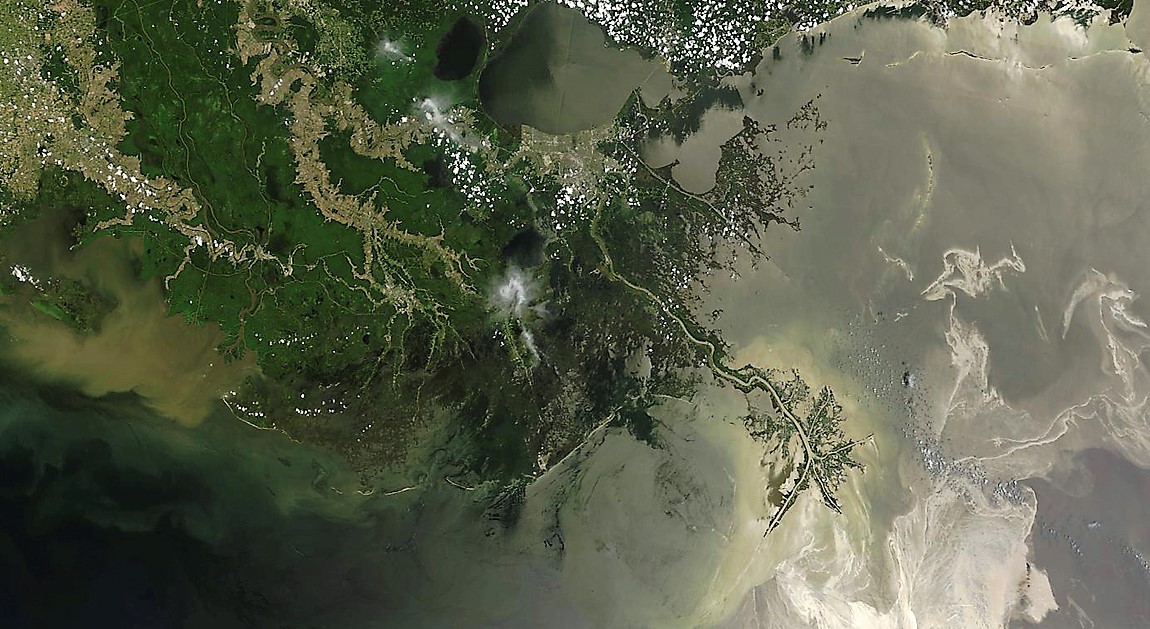

Recent government directives require oil and gas companies to submit to the governmental commission on FEC (Fuel and Energy Complex) programs for the reconstruction of intra-field pipelines. Back in 2016, several inspection authorities compiled the most comprehensive list of contaminated lands using satellite imaging data. Simultaneously, the Russian Ministry of Natural Resources advocates for a hundredfold increase in fines for concealing oil spills, unpreparedness for their elimination, or providing incomplete information about contaminated areas. Near-infrared (NIR) and shortwave infrared (SWIR) ranges of satellite imaging are used to identify contaminated areas and damaged vegetation.

Satellite imaging, combined with the latest achievements in information technology, allows for a significant acceleration of pipeline and security zone monitoring through deep learning classification of satellite images. By running a satellite image processing algorithm, a GIS specialist can survey and record foreign objects, withdrawal zone violations, and oil spills dozens of times faster than with traditional visual interpretation. The only challenge in automated interpretation is the accumulation of reference samples of the territory. However, companies experienced in processing satellite images have a substantial reference base, enabling immediate commencement of surveying. Additionally, using images taken at different times allows for monitoring changes in the area, automatically detecting all alterations from deforestation to construction.

Leading global space companies, such as Maxar Technologies Inc (formerly DigitalGlobe), have developed geospatial portals for automated processing, interpretation, and object detection from satellite imagery. For example, Maxar's GBDX (Geospatial Big Data) product utilizes a vast archive of high-resolution satellite images and previously developed interpretation algorithms from top IT companies worldwide. The program runs on Amazon's servers, drastically speeding up the processing of massive remote sensing data.

The detection of pollutants along pipeline routes is also significant.

There is a remote sensing service that uses satellites like Dove for daily surface scanning and image collection specifically for pipelines. After uploading the image, the vegetation indices are automatically calculated, vegetation health values are generated, and change detection analysis is performed. A deterioration in vegetation health signals an abnormal situation at the pipeline location and can be associated with pollutant releases. This software acts as an early detection system, regularly assessing the right to monitor quickly to mitigate surface and underground releases by accurately identifying problem areas (Figure 4).

Fig. 3. Identified problem areas based on vegetation assessment along the pipeline route

Detection of ground deformation along the pipeline route

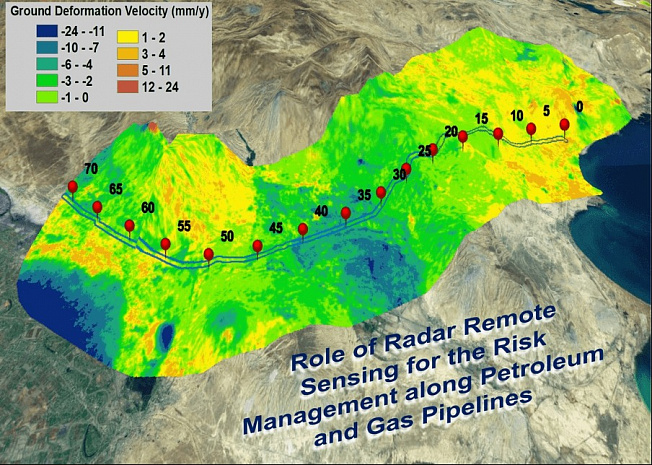

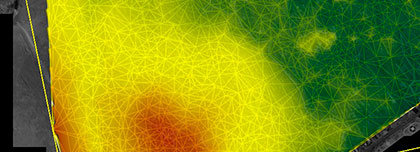

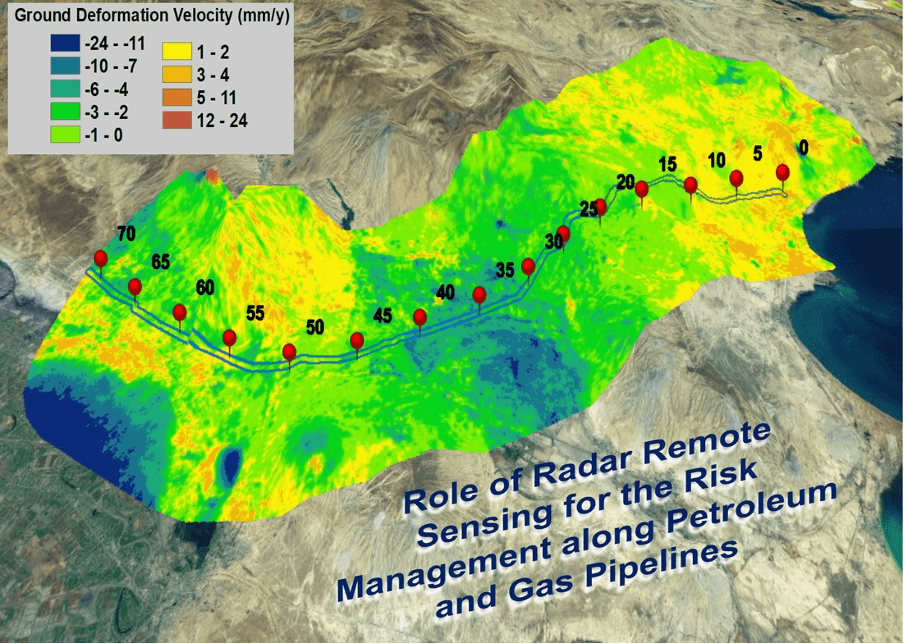

Based on remote sensing data, both satellite and UAV, automated quantitative assessments of surface deformation rates and their natural and anthropogenic driving factors are conducted as potential risks along, for example, a seismically active underground oil and gas pipeline using persistent scatterer interferometry (PS-InSAR) and small baseline subset (SBAS) remote sensing analysis. This approach significantly improves ground deformation monitoring, assesses geological hazards and preventive measures along pipelines. The diverse spatial distribution and variability of ground movement processes along pipelines have shown that general geological and geotechnical understanding of the study area, without remote sensing monitoring, is insufficient to identify and eliminate all critical subsidence and uplift sections for pipeline operators.

Fig. 4. Ground deformation levels along the pipeline route

For prompt monitoring of the main pipeline and withdrawal zones and assessment of environmental impact, contact "Innoter" at +7 495 245-04-24 or send a request to innoter@innoter.com. Years of experience using satellite imagery in the oil and gas industry will help solve your tasks quickly and efficiently.

Monitoring the technical condition of pipelines using satellite imaging and UAVs is one of the methods that can be employed to ensure the safe transportation of oil, gas, and other liquids through pipelines under various operating conditions.

Diagnostic and monitoring systems for the technical condition of pipelines include various equipment that can be used to detect defects and issues in pipelines. These can be systems for monitoring temperature, pressure, and other parameters, as well as non-destructive testing systems such as ultrasonic devices and X-ray machines.

However, the use of satellite imaging and UAV methods can be a valuable addition to existing methods for monitoring the technical condition of pipelines. They can be particularly useful for detecting damage in hard-to-reach locations and for monitoring a large number of objects over extensive areas.

It is also important to note that systems for monitoring the technical condition of pipelines must operate under various operating conditions, including extreme environments such as high and low temperatures, high pressure, etc. This may require the use of specialized equipment and methods to ensure the accuracy and reliability of the data obtained during pipeline monitoring.