Digital Topographic Map (DTM) is a digital model of the terrain recorded on a machine-readable medium in an established structure and codes, in the projection, grid, coordinate system, and heights adopted for the map, with accuracy and content corresponding to a specific topographic map scale.

DTMs are created in scales of 1:10000, 1:25000, 1:50000, 1:100000, 1:200000, 1:500000, 1:1 000 000, and formed as arrays of digital cartographic information (multiple objects of DTM) covering areas of territory, limited by the frames of sheets of corresponding topographic maps of the same scale.

You can order from us

Prices for services

| Consultation | Free of charge |

|---|---|

| Search for images, preliminary analysis of the availability of source data, additional and reference materials | Free of charge |

| Ordering images |

|

| Cost of creating a DTM (Digital Topographic Map) |

|

| Cost of creating (updating) 1 sheet of a digital topographic map |

|

| Execution time | From 20 working days (depends on the volume, complexity, availability of remote sensing materials, additional and reference materials). |

The cost of execution is calculated on an individual basis, taking into account a specific of task.

After receiving the task description, we calculate the cost and send you a commercial offer.

Period of execution

The completion period for the work is at least 20 (twenty) working days.

The actual duration of the work depends on several factors, including:

- The area of interest or the extent of the region being mapped.

- The scale and type of the digital topographic map being created.

- The availability of existing archive materials from remote sensing data.

- The availability of additional and reference materials required for the project.

These factors can affect the complexity and scope of the project, which in turn impacts the time required for completion. The mentioned 20 working days serve as a minimum timeframe, and the actual duration may vary based on the specific requirements and resources available for the project. It is essential to consider all these factors during the planning and execution of the mapping work to ensure timely and accurate results.

How to place an order:

Need for consultation?

Fill the form and we will contact you

Stages of service provision

The result of the provision of services

- Cartographic products (digital topographic maps) in formats, projection, coordinate system, and heights specified in the Technical Task;

- Remote sensing data (DSM) in the form of digital orthophotoplans and original images;

- Set of additional and reference materials used in the work;

- Editorial and technical instructions;

- Technical report on the completed work.

Transmission methods:

- Electronic media;

- FTP server;

- Hardcopy (for text materials).

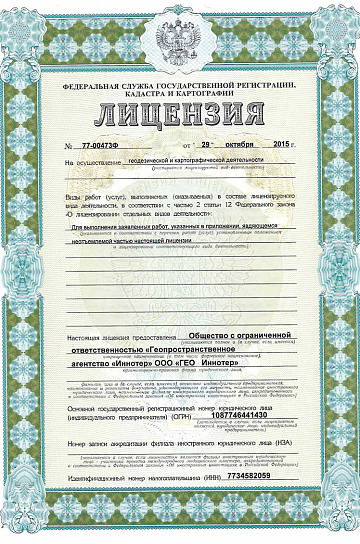

The work is also carried out in accordance with the requirements of regulatory and technical documentation on ensuring the confidentiality regime in the Russian Federation.

When ordering a digital cartographic basis for a production area in multiple scales, the largest scale is used to create smaller scales.

The digital cartographic basis is provided to the Client in electronic form in the specified format according to the Client's classifier and Classification Principles.

When creating and updating the digital cartographic basis of any scale, the object composition is unloaded to a state for public use.

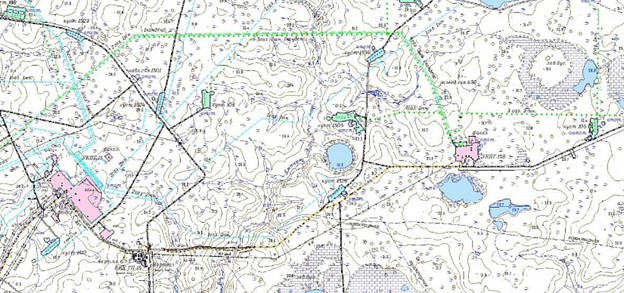

Figure: Example of a topographic map at a scale of 1:10000

Requirements for Source Data

In order to perform preliminary work qualitatively, the following must be provided:

- Coordinates of the mapping area (in any convenient form);

- Scale and type of the created (updated) digital topographic map, format of presentation, in which breakdown to provide data (by nomenclature sheets or within the mapping area), projection, coordinate system, and heights;

- Availability of source map materials, additional, and reference data;

- Lists of coordinate control points for photogrammetric processing of DSM materials;

- Requirements for the object composition, semantic information of the created (updated) digital topographic map;

- Necessity of developing and agreeing on Editorial and Technical Instructions for the creation (updating) of the product.

|

Requirement Name |

Requirement Values for Scales |

||||

|

|

1:2000 |

1:5000 |

1:10000 |

1:25000 |

1:50000 |

|

Allowed resolution on the terrain Lм, (spatial resolution of images) m |

0.1 |

0.25 |

0.5 |

1.25 |

2.5 |

If it is not possible to provide the specified information, it is necessary to provide information about the purpose of using digital topographic maps and the types of work planned to be carried out using them. Experts from "GEO INNOTER" will analyze the information and prepare the optimal proposal for creating (updating) digital topographic maps.

Related services

Completed projects

Customers

FAQ

- area of interest (location / coordinates of the object in any convenient form, and area of the object);

- the specific problem to be solved using the digital topographic map

- Recognition on the terrain and determination of coordinates and heights of planimetric and height control points using GNSS receivers.

- Creation of a digital elevation model of the earth's surface.

- Creation of digital orthophotoplans at a scale of 1:5000.

- Field decoding based on digital orthophotoplans.

- Creation of a digital cartographic basis at a scale of 1:5000 with contour lines at intervals of 1 meter.

- Performing digital aerial imagery and airborne laser scanning.

- Creation of a geodetic network of GNSS base stations and reference marks using satellite geodetic dual-frequency equipment.

- Creation of a digital elevation model based on laser reflection cloud data.

- Creation of digital orthophotoplans with a resolution of up to 0.10 meters.

- Field decoding of infrastructure objects across the entire area of aerial imagery.

- Creation of a digital cartographic basis at a scale of 1:5000 with contour lines at intervals of 1.0 meter.

- Creating a planimetric and altimetric justification for the satellite imagery.

- Building a digital elevation model.

- Performing exterior orientation and orthotransformation of the satellite images.

- Digitally creating maps at a scale of 1:25000 based on orthophotoplans.